CutMaker Software+MCS Control Card

Main Configurations

|

Maximum Operating Acceleration |

2G |

Maximum Operating Speed |

150m/min |

|

Positioning Accuracy |

0.001mm |

Repeated Positioning Accuracy |

0.003mm |

|

Special Output |

2 DA |

Special Input |

8 limitation switch,4 starting point |

|

Output |

20 |

Input |

16 |

System Structure

Advantages

Convenient Functions

1.Error measurement; 2.Nano cutpoint; 3.Diverse edge offset; 4.Multi-station; 5.Dust removal for designated zones; 6.Automatic adjustment; 7.Cutoff by one processing; 8.Intelligent fly cutting.

Automation

1.Intelligent movement; 2.Visual positioning; 3.Custom PLC; 4.Multi-file processing; 5.Dual station; 6.Air pressure calibration; 7.Laser interferometer

Processing Module

1.Starting line processing; 2.Fast piercing processing; 3.Layer processing with high precision

Software

Applications

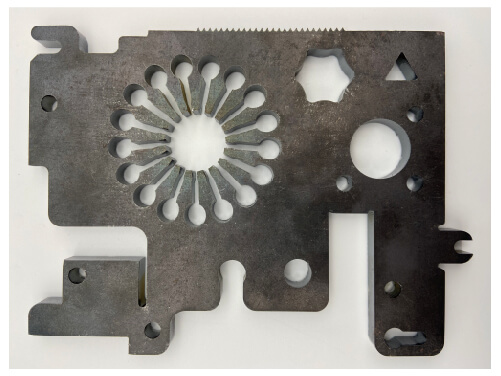

Auto Parts

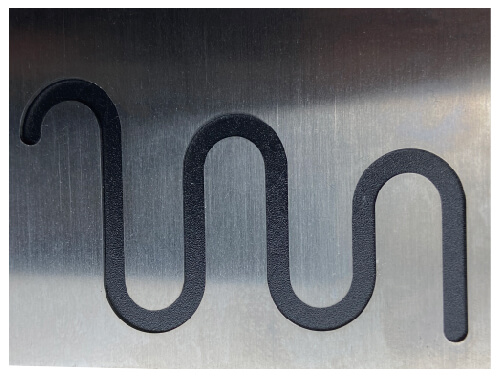

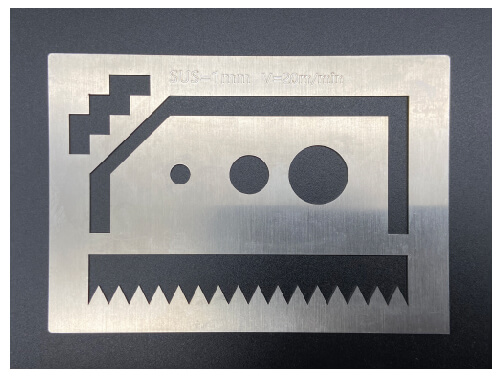

JCZ laser cutting system is able to cut various automotive materials, such as low carbon and low alloy steel, high strength steel, atmospheric corrosion resistant steel, ferritic stainless steel, austenitic stainless steel, and aluminum alloys, and almost all automotive plates of various texture. Its S-type acceleration and deceleration algorithm make higher positioning accuracy and faster running speed possible in the cutting of auto parts, as well as increasing the processing accuracy, quality, and efficiency of auto parts.

3C Electronics

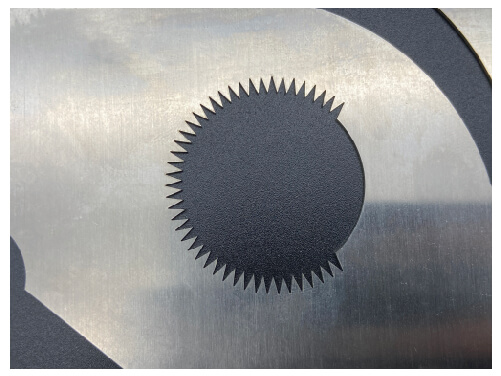

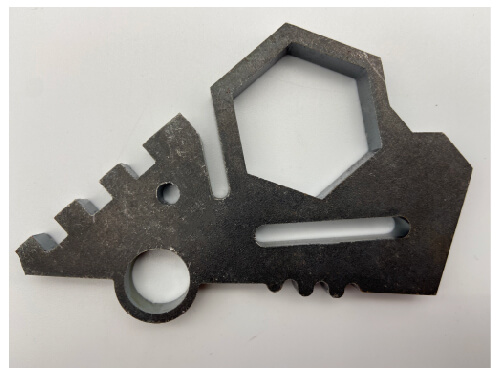

JCZ laser cutting system can perform precision cutting or micro-hole processing on small workpieces, such as metal or non-metal parts, with the advantages of high cutting accuracy, high speed, and low heat impact. Its multi-station and PLC function is widely used in the cutting of electronic products including cell phones, laptops, and cameras. Its main advantages of accurate processing size and clear contour make it possible to improve the cutting quality, especially for the fine processing of various high-end materials with high hardness, high brittleness, and high melting point. In addition, its non-contact cutting furthers the product yield compared with traditional tool cutting.

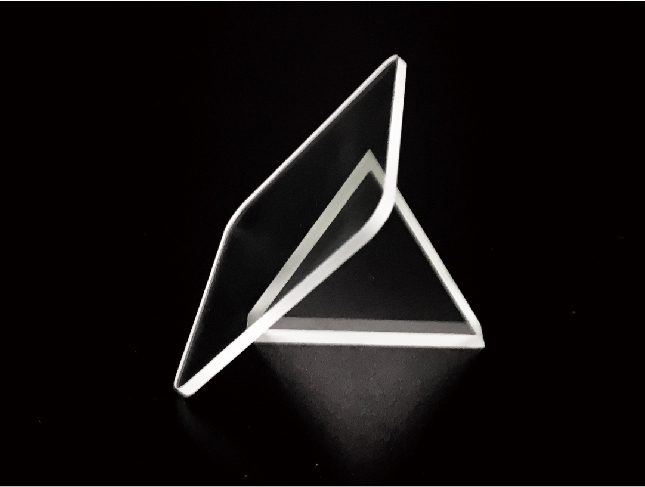

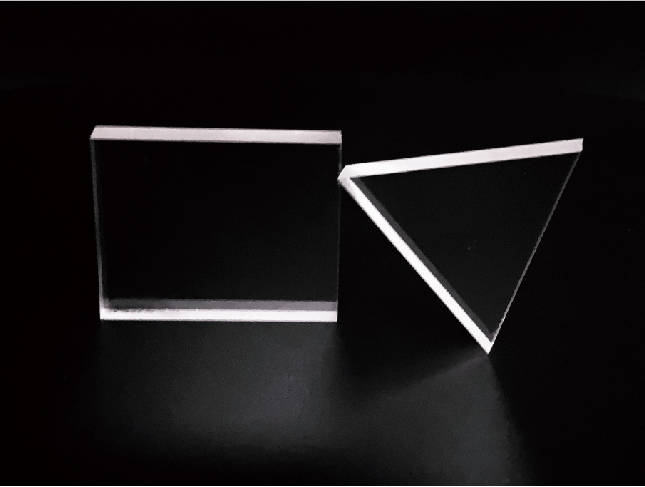

Glass Cutting

The cutting of brittle materials, for example, glass is a new application in laser processing. Combining the ultra-fast laser with the PSO function of JCZ laser cutting system (arc-cutting at 500mm/s speed, point spacing accuracy ±0.2um), glass cutting with high speed and high precision can be actualized. Moreover, with the spliting post-processing, high-quality glass finishes are gained.

|

|

|

|

|

|

|

|

|

|

Contact Us

Service Hotline

Email: Click Me

Telephone:010-64426993/95

Headquarter: #22 Building, #13 Mintai Road, Shunyi District, Beijing City, China,101300.

Main Factory: 4th Floor, #15 Building, #13 Mintai Road, Shunyi District, Beijing City, China,101300.

Suzhou JCZ Technology Co., Ltd.

Address: m3-103-2, microsystem Park, Suzhou science and Technology City, No. 2, Peiyuan Road, Huqiu District, Suzhou, Jiangsu

Guangdong JCZ Technology Co., Ltd.

Address: room 1002, No. 4, Songhu Zhigu R & D center, No. 1, renju Road, Liaobu Town, Dongguan City, Guangdong Province

Beijing JCZ Technology Co., Ltd. Wuhan Branch

Address: 1101, block B, building 1, modern service industry base, Huagong science and Technology Park, University Park Road, Jiangxia District, Wuhan, Hubei Province

Copyright © 2022 Beijing JCZ Technology Co., Ltd. 京ICP备18045191号-1