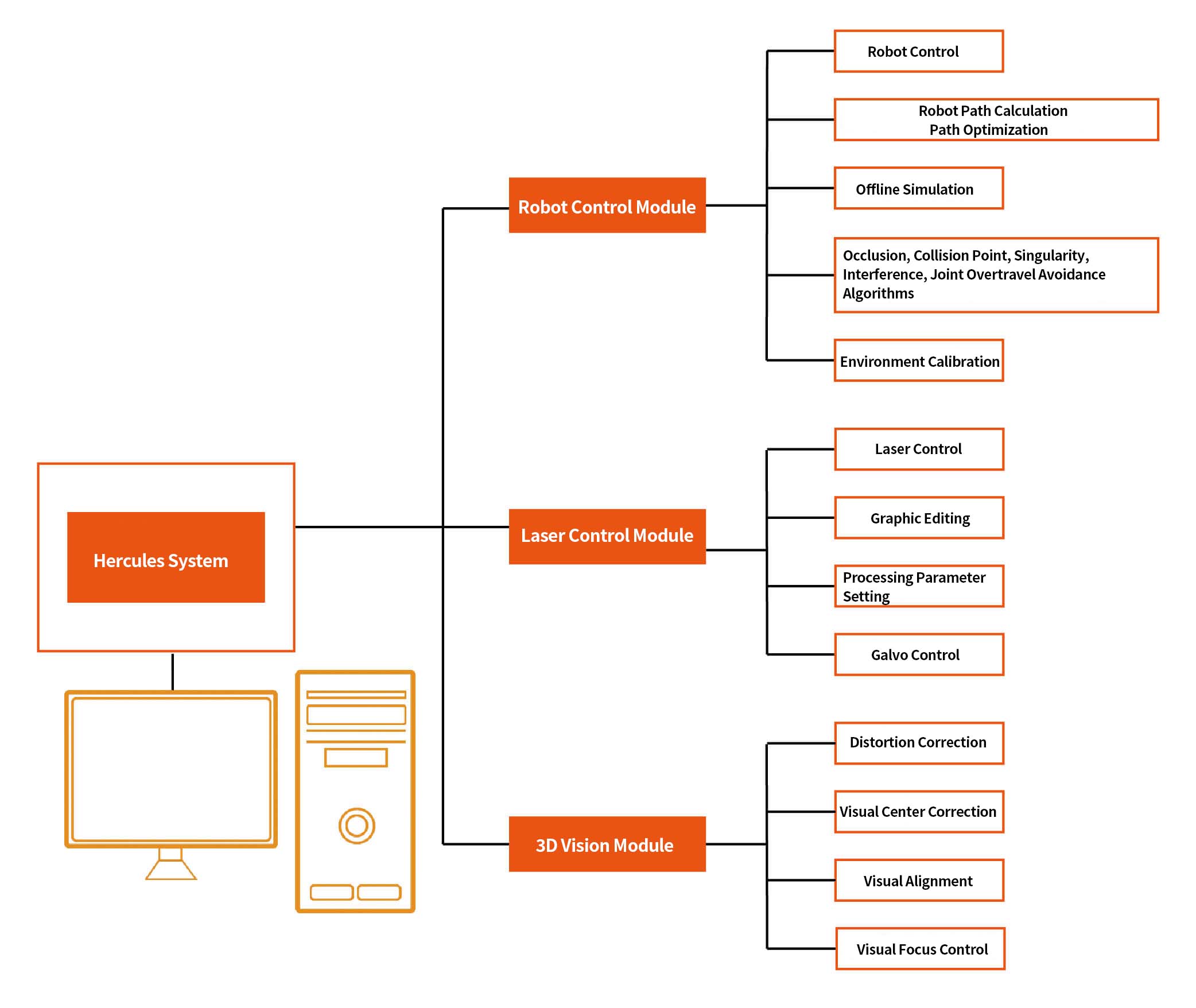

Hercules System

Software Interface

System Structure

Characteristics

Flexibility

Automated mechanical laser processing with changing processing objects can be achieved.

High Accuracy

Laser processing for multi-angle precise splicing on shaped workpieces can be achieved.

High Efficiency

The system is equipped with the 3D Galvo to effectively complete 3D processing.

Advantages

Intelligence

Hercules system has a trajectory configuration function, which can replace manual cutting of processing content and manual design of robot motion trajectory. The system has an unknown detection function, which can solve manual verification of collision, singularity, interference, and overtravel.

|

|

|

|

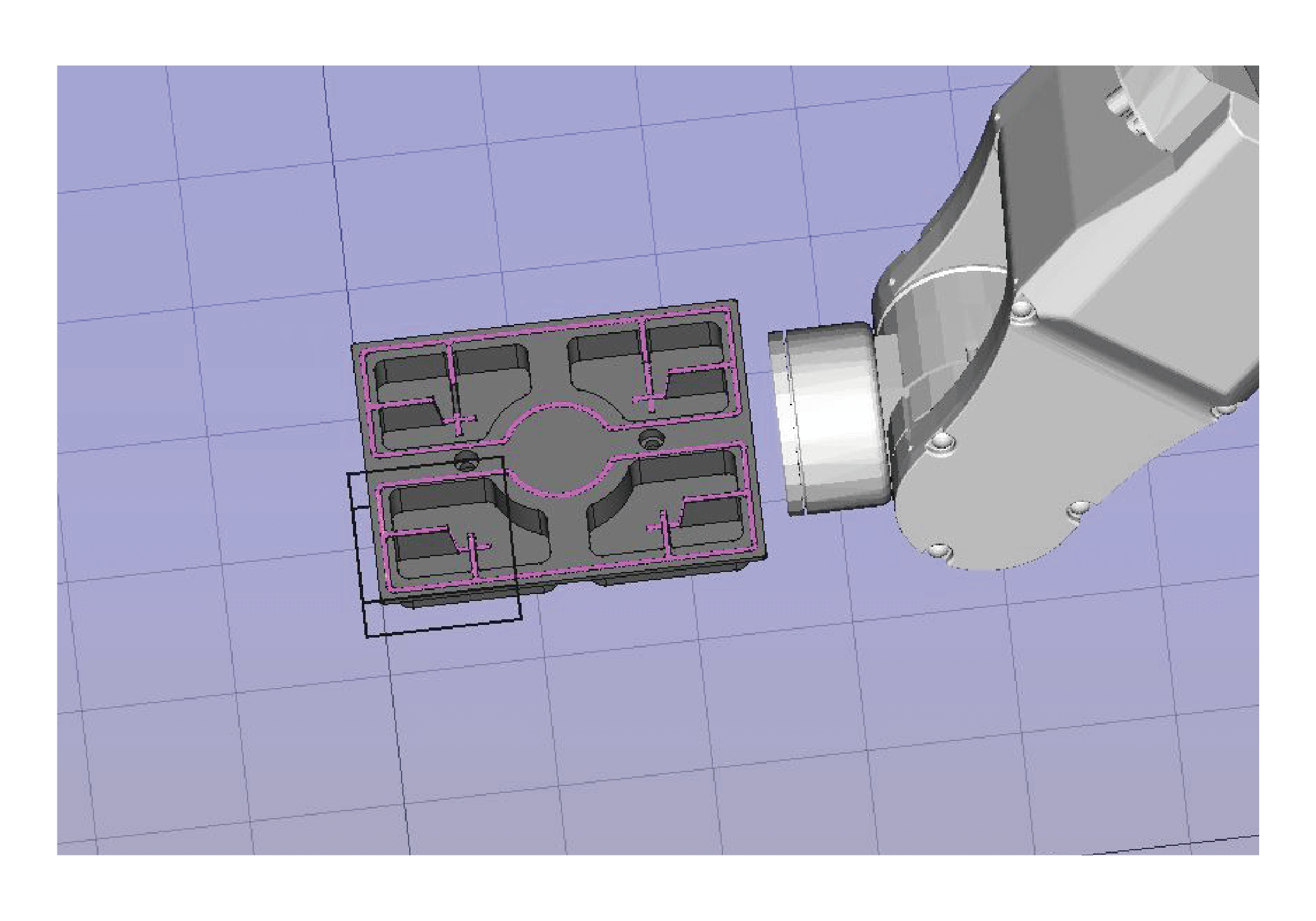

The purple part is the processing path for graphics obtainment |

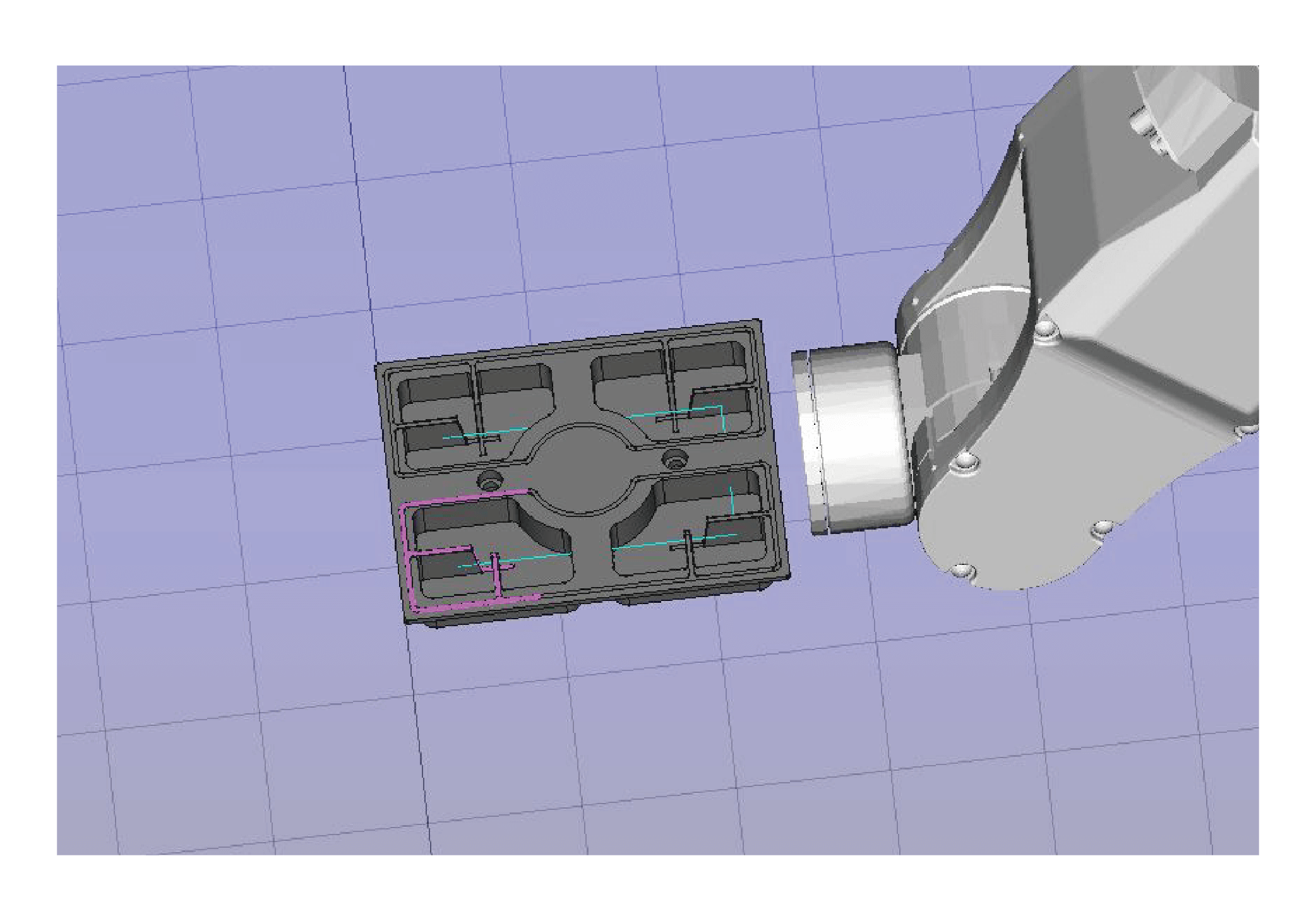

Processing path by auto-splitting |

Reduction

Steps of projecting and wrapping 2D graphics to 3D models are removed. The processing graphics can be obtained directly from the surface of the 3D model. The extracted 3D processing graphics can be edited, moved, and rotated. This method effectively avoids the distortion of projection and wrapping algorithm.

Comprehensiveness

The position of the robot, scanner and workpiece can be set. According to the selected processing content, the laser processing path, robot motion trajectory, and 3D visual positioning are automatically generated.

3D Laser Processing

Both efficiency and accuracy can be achieved by the use of the scanner.

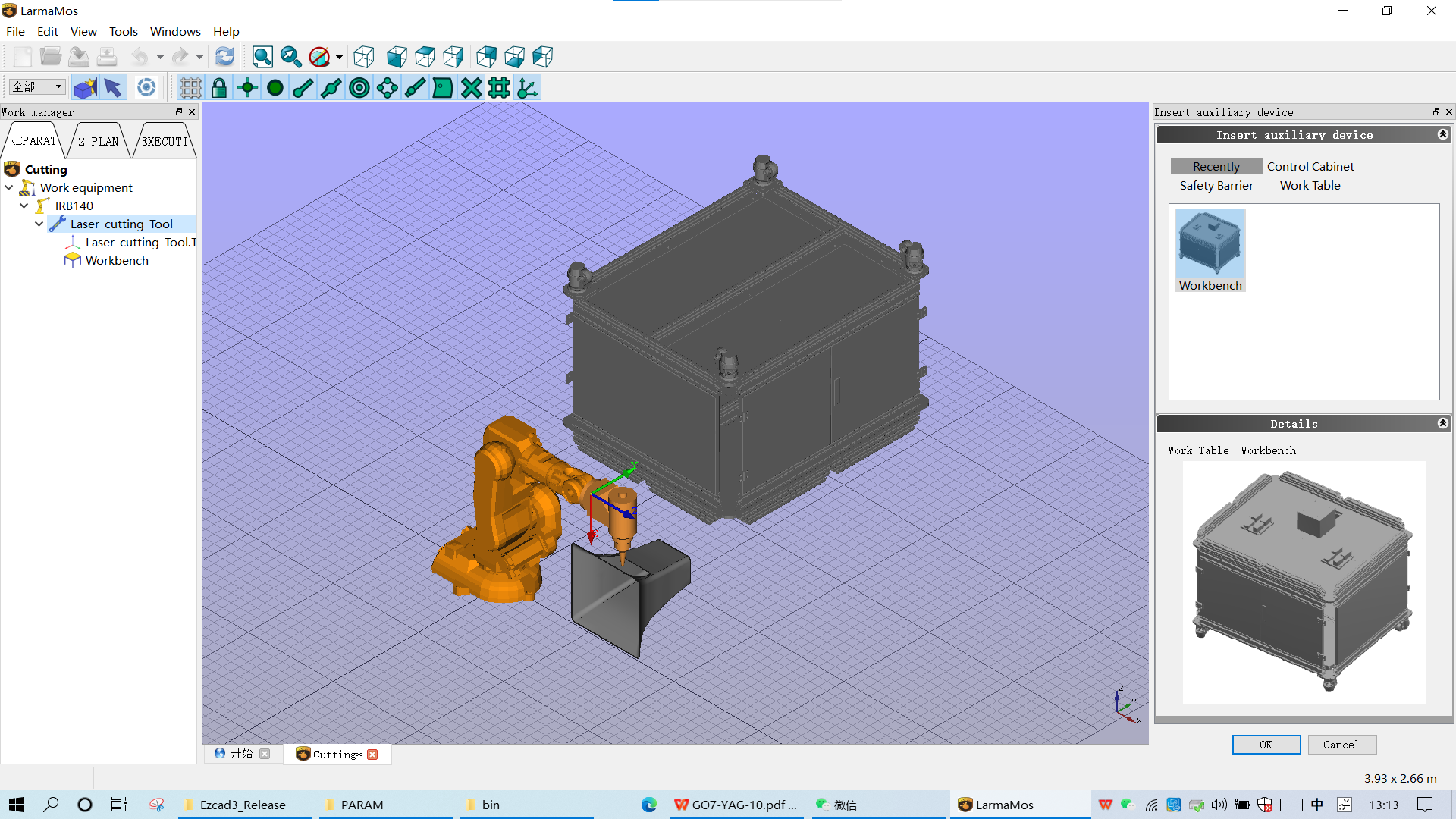

Robot Control

It is compatible with 12 brands of more than 100 models of robots with more realistic virtual scenes and procedure design.

Three-dimensional Vision with a Robot

Its function of self-developed special 3D vision with a robot simplifies debugging.

Applications

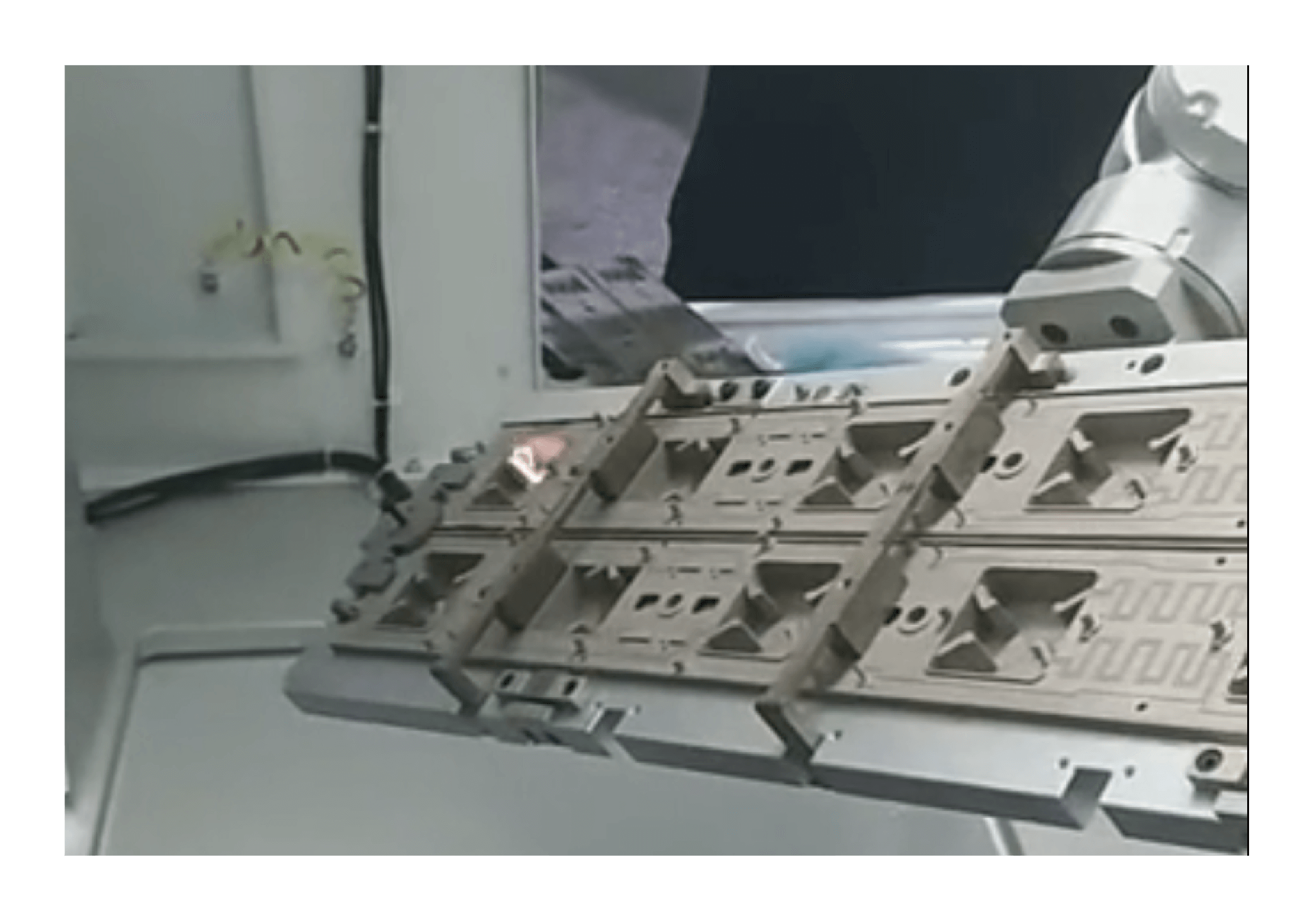

Processing of 5G Antenna Components

The processing of complex cavity structures in 5G base station antennas by traditional 2D laser processing is difficult. High precision processing on complex surfaces with high flexibility is possible by the combination of the robot, the 3D dynamic scanner, and the spatial image positioning technology.

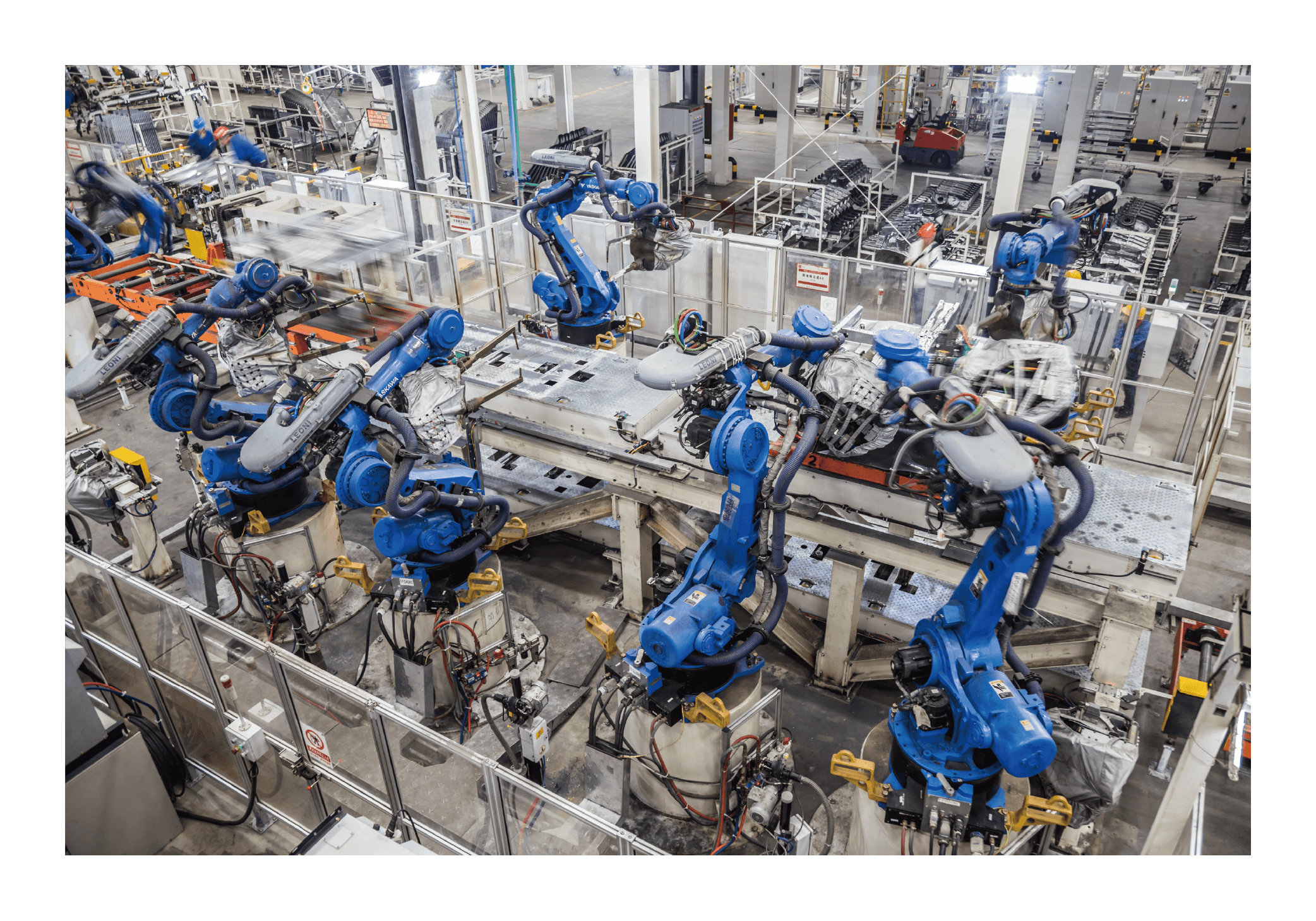

Remote Welding of Body Parts

Laser welding has been widely used in the modern production of body parts. The combination of the robot and the 3D scanner for laser welding makes welding position flexible without contact with workpieces. The synchronous operation of the robot and laser welding by the scanner largely eliminates the waste of non-productive time caused by constant repetitive positioning before each welding, thus maximizing the processing time of the laser beam and improving productivity. The system is widely used for welding automotive seat panels, instrument-related parts, door structural parts, trunk lids, new energy battery modules, plastic parts, and other products.

Laser Cleaning of Large and Complex Workpieces

Conventional laser cleaning equipment is mostly handheld, which makes cleaning effectiveness and stability hardly guaranteed. Therefore, processings that require demanding processing environments, such as aircraft fuselages, combat vehicle bodies, reactors, and large rubber molds are subject to many restrictions. By comparison, Hercules system can meet these stringent requirements. The system combines the robot and the laser cleaning head and can be applied in the cleaning of large tire molds.

Contact Us

Service Hotline

Email: Click Me

Telephone:010-64426993/95

Headquarter: #22 Building, #13 Mintai Road, Shunyi District, Beijing City, China,101300.

Main Factory: 4th Floor, #15 Building, #13 Mintai Road, Shunyi District, Beijing City, China,101300.

Suzhou JCZ Technology Co., Ltd.

Address: m3-103-2, microsystem Park, Suzhou science and Technology City, No. 2, Peiyuan Road, Huqiu District, Suzhou, Jiangsu

Guangdong JCZ Technology Co., Ltd.

Address: room 1002, No. 4, Songhu Zhigu R & D center, No. 1, renju Road, Liaobu Town, Dongguan City, Guangdong Province

Beijing JCZ Technology Co., Ltd. Wuhan Branch

Address: 1101, block B, building 1, modern service industry base, Huagong science and Technology Park, University Park Road, Jiangxia District, Wuhan, Hubei Province

Copyright © 2022 Beijing JCZ Technology Co., Ltd. 京ICP备18045191号-1